What to Know About Caulk Removal and Replacement

What to Know About Caulk Removal and Replacement

Caulk removal and replacement are some of the simplest ways to improve the quality of a building structure and its energy savings. However, incorrectly removed or applied caulk can cause more problems than it solves. If you have never thought about replacing old caulk around your commercial property, it’s already past the time to complete this chore. Find out what to do to remove the old caulk and replace it with new caulking.

When to Remove Caulking

Caulking does not last forever. With frequent exposure to the elements, it will wear out sooner. If the caulk wasn’t applied by a knowledgeable craftsperson, the surface might not have been prepared appropriately, or the wrong caulk could have been applied. This can lead to premature wear and peeling.

Peeling caulk does not create a tight seal. Water, insects and cold air can all seep through the gap created by worn caulk. Left unchecked, these issues can worsen until the area protected by the caulk sustains serious environmental damage. For instance, a window with caulk around it could receive water damage on its frame, leading to mold and dry rot of wooden frames. Carefully preparing the surface and applying a new caulk with a tight seal can lengthen the caulk’s life span and prevent peeling or cracking.

Mildew or mold growing on caulk indicates the material no longer provides adequate protection from these organic substances. Mold growing on the caulk’s surface could signal that moisture has penetrated under the material, causing mold growth beneath it, too. Mold causes several problems such as allergies and physical damage to structures.

Mold or mildew-covered caulk needs replacement as soon as possible. While waterproof caulk can prevent mold or mildew from growing, it can still allow moisture if a knowledgeable person did not apply it with a tight seal.

If you schedule any building renovations, remove the old caulk and replace it. If your renovations involve replacing doors, windows or flooring, remove the old caulk and have a professional replace the sealant.

Typically, properly applied caulk in an indoor location should last around five years. However, other signs aside from age will indicate you need to remove the caulking and replace it. Even if your caulk does not show indications of wear, invisible damage and stress may compromise its effectiveness over time. Therefore, schedule caulk removal and replacement for at least every five years.

Schedule caulk removal and replacement for your facility with Houck today!

Does the Type of Caulk Matter?

The type of caulk does matter, especially in how you use it and how you must remove it. For instance, silicone caulk is the toughest type to remove. The following are common types of caulk and their most frequent applications.

Silicone Caulk

Silicone is a durable, flexible caulk material that works best to seal glass, metal, ceramic and porcelain. It can withstand cold weather, ultraviolet (UV) rays, mold and mildew extremely well, making it ideal for unheated spaces or outdoor applications. For curing, silicone does not require warm conditions, unlike other sealants. After application, the sealant remains soft and pliable.

Unfortunately, silicone will not adhere to wood or dried silicone. You also cannot paint over it because the paint will not adhere to the caulk. Additionally, if something physically damages the silicone to cause a tear in it, the rest of the caulk will also rip away easily.

Despite its shortcomings, silicone remains a top choice for sealing nonporous surfaces in extreme environments.

Water-Based Caulks

Several types of sealant fall into the water-based category — latex, acrylic and vinyl. Water-based caulks adhere to most types of building materials, including nonporous surfaces and wood. These caulks are among the easiest to work with because they only require water for cleanup, as long as the material has not dried. Plus, after curing, you can paint the surface to match the surrounding material. Acrylic has UV resistance and can work well in exterior applications if needed. Plus, this type of water-based sealant does not shrink.

The downsides to water-based sealants include their application methods. Acrylic is more difficult to apply than water-based latex. All sealants in this category require warm, dry conditions for the fastest, most secure curing. Lastly, unlike acrylic, latex tends to shrink and allow water penetration, making it only useable for interior applications.

Polyurethane Caulks

For tough, long-lasting sealants, polyurethane caulks are a good option. Contractors tend to choose this material for caulk due to the wide range of materials it adheres to and its durability. Polyurethane sealants provide a paintable surface that resists abrasion and shearing damage, making these the best option for high-traffic areas.

Despite polyurethane’s durability, though, this material requires careful handling to avoid exposure to its odorous, noxious fumes.

Butyl Sealants

Butyl caulks adhere well to many types of surfaces. However, its strong water resistance works best for exterior applications, such as rain gutters, roof flashing or foundations.

Unfortunately, butyl sealants have a stringy texture that makes application very difficult. Butyl caulks also do not stand up to abrasion as well as polyurethane versions.

Synthetic Rubber Caulks

Solvent-based synthetic rubber caulks have properties similar to those of both water-based and silicone caulks. Like water-based sealants, synthetic rubber types adhere to most types of construction materials. Application conditions can be cold and wet or hot and dry like silicone caulks. However, unlike the other types of caulk, synthetic rubber varieties stretch well after curing. For joints that move frequently, the flexibility of synthetic rubber sealants works best.

The disadvantages of these sealants are their flammability and high volatile organic compound (VOC) amount. Most solvent-based caulks have higher VOCs compared to water-based types. The high volume of VOCs in synthetic rubber caulks makes these sealants unsafe for interior applications.

Contact Houck to learn more about the best caulking solutions for your needs.

How to Soften Caulk for Removal

While some types of caulk yield to pressure from a putty knife, not all will peel off with such little effort. You may need to use a softening solvent to prepare the caulk for removal, especially for more durable caulk types, such as silicone.

Homemade Caulk Softening Solutions

Some homemade options for softening caulk will work well for soft water-based acrylics or similar sealants. These solutions include using isopropyl alcohol or warming the caulk with a hairdryer. The heat will only work to soften more delicate types of caulk.

Commercial Caulk Remover Formulas

For difficult-to-remove silicone or other caulks, you will need a commercial caulk remover to soften the material. Caulk removers have different formulas that can disintegrate various materials. While some brands may work with all types of caulk, others will only work with water-based latex or silicone types. Read the instructions before finalizing your purchase to make sure you buy the correct remover for your job.

To soften the caulk with one of these preparations, always read all directions first. You will likely need to ventilate the area well to prevent a buildup of noxious fumes during the process. Test a small area with the remover solution to verify it will successfully soften the caulk type and not harm the material surrounding the caulk.

The softener formula you use could require hours to work. Once the softener finishes its portion of the removal process, you will still need some manual work to remove the caulk. However, the caulk will be softer and easier to peel off the surface after softening.

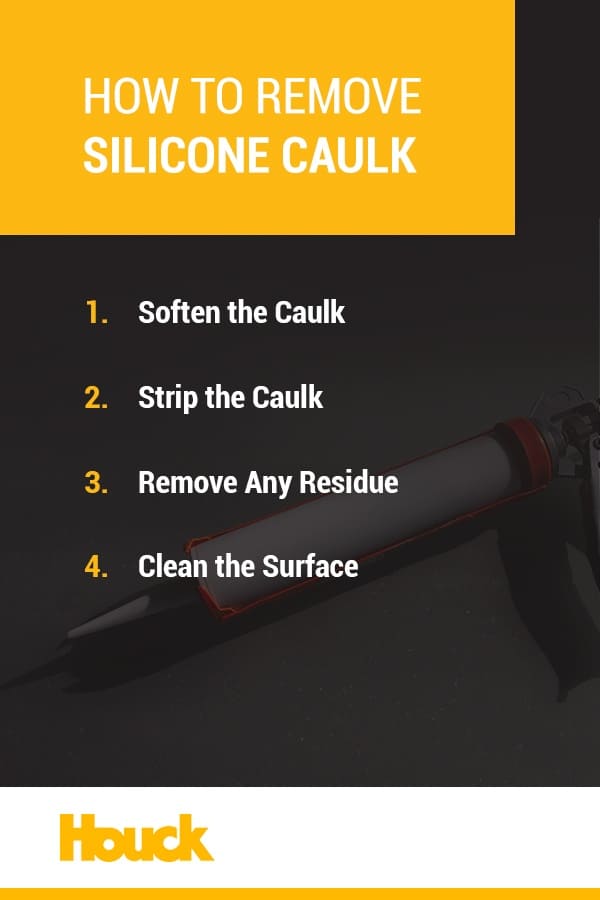

How to Remove Silicone Caulk

Silicone caulk sticks to surfaces tightly. Therefore, it can be one of the most difficult materials to remove completely. You must have adequate ventilation when removing this or any other type of caulk to avoid inhaling fumes from chemical caulk softeners. Also, you cannot leave any residual caulk in place. Doing so will reduce the new caulk’s ability to adhere to the surface, shortening its life and compromising its performance.

Here are a few steps for getting rid of silicone caulk:

1. Soften the Caulk

First, soften the caulk using either a commercial caulk remover or homemade preparation. Whichever product or method you choose will require several hours to soften the sealant enough for removal. Don’t rush this step. You may need to let the softener work for at least four hours before returning to the removal task. The time you invest will be worth the wait because the softer the sealant becomes, the easier the following steps will be.

2. Strip the Caulk

Use a putty knife, utility knife or a caulk removal tool to peel off the sealant. When using a sharp blade to strip away the caulk, be careful not to scratch the surrounding material. Try to peel the sealant off in strips to avoid leaving behind small pieces. For caulk in tight spaces, you may try a needle-nose plier, too.

If you correctly used the caulk softener product in step one, the sealant should easily peel away in strips instead of shattering into small bits.

3. Remove Any Residue

Get rid of any residue remaining by warming the caulk with a heat gun or hairdryer. For heat-sensitive areas, soak a towel in rubbing alcohol and place it over the caulk remnants for a day or two to soften the last of the caulk. As with the initial softening stage, don’t rush this portion of the caulk removal. You must not leave any residue behind or the new caulk will not adhere well.

Clean off this residue and scrub away any pieces of caulk from corners with a small toothbrush, putty knife, caulk removal tool or utility knife. Since fresh silicone sealant will not adhere to cured silicone, you must ensure a tight seal of the new caulk through proper cleaning.

4. Clean the Surface

After you remove every last bit of sealant, you must still clean off the surface well to prepare it for fresh caulk. Old caulk may have allowed moisture through, causing mildew or mold growth underneath. Clean off the mildew with diluted bleach to kill the organisms and freshen the area.

Get in touch with the experts at Houck for quality caulk removal.

The Benefits of Professional Caulking and Sealing

While you may remove old caulk and prepare the surface yourself, hire a professional for applying a new sealant. Applying caulk is an art in handling this material. The process is also a science in selecting the appropriate type of sealant for an application. Therefore, for the best results, a trained craftsperson should be the one to apply caulk to your commercial building.

For example, several factors go into determining the correct sealant for a commercial property. Some building locations will need flexible caulking that moves as the joint does, preventing cracks and avoiding damage from shearing forces. Heat and moisture resistance are needed in exterior joint seals. Cleanliness and mold or mildew growth prevention may perform well in a lab or other medical settings with high sterility requirements.

Well-trained craftspeople know which sealant has the properties required to meet a commercial site’s needs. When working with a professional, you’ll get recommendations for long-term performance and repairs of caulk failure points.

Professionally caulked commercial sites have joint seals that keep out pests and moisture. The ability of well-sealed buildings to maintain temperature will also reduce energy usage for heating and cooling. Additional benefits include aesthetic appeal, especially in historic buildings, and prevention of mold and mildew in the area.

A well-sealed building will save money in utility bills and reduced moisture damage repairs. The cost of hiring a professional team for caulking your commercial site will provide returns on your investment in the comfort, durability and longevity of an expertly applied sealant.

Contact Houck for Commercial Caulk Removal and Replacement

For more than 70 years, the craftspeople at Houck have provided caulking services for commercial property restoration and preservation. On every page of our site, you will see testimonials from businesses we have helped with our past services. Their words back up our mission to promote safety first, use a qualified team for each job, exceed all expectations, be flexible when needed and build trusting relationships with our clients.

When you contact us for professional joint sealing services or caulk removal, you get a team of highly trained and qualified craftspeople to properly seal all the joints in the structure. Due to the nature of caulk replacement, attention to detail is vital for a lasting seal. Our team members put diligence into each task they do, including caulk removal and replacement.

We put the same effort into restoring the caulking for small, historic structures and large, modern buildings. We let our years of work in the mid-Atlantic region guide us in our historic restorations. With special training to incorporate modern sealing methods with historic building designs, our team members use the most up-to-date methods to protect these buildings without compromising their historic integrity. Our services also apply to modern properties. No matter your building’s age, if you need professional caulking and sealing services, let us at Houck know.

Reach Out to Us at Houck

To get more information about Houck or schedule a comprehensive estimate for your commercial caulking jobs, contact us today. We look forward to partnering with you to improve your property’s structure through our caulking and other commercial services by providing you with safety, quality and performance.